Finish

UV Oil

Ultra-violet dried oiling process, an effective way of finishing, products are immediately ready to be handled afterwards. Maintenance: needed regularly.

UV LACQUER

Similar to UV Oiling process in essence. It normally consists of 9 layers lacquer which results in a more coated look and feel. Maintenance: not needed; the weared coating cannot be repaired either.

HARDWAX OIL

The common finish of wooden flooring, 24 hours of air drying after each application run is needed before the next production step. Manitenance: necessary.

UNFINISHED LOOK

The popular finish nowadays, Invisible Oil is applied as the primer, brings the wooden surface unfinished effect but well protected by topcoat like UV Oil / UV Lacquer / Hardwax Oil. Manitenance: depending on the type of final coating.

Texture

BRUSH

Done by machine driven brushes, opens the pore of the wood and leaves more vivid touch.

DISTRESS

Make the top layer look aged, the effect is reached by a rolling pin with hard solid objects on the body.

HANDSCRAPE

A predominantly mechanical process, classified by machine and mannual, making a wavelike grained surface with "hills and valleys", the square edges are thereupon treated.

EMBOSS

Upgraded and more manually extensive mechanical treatment, naturally and vividly embossing along the wood grain and around the knot, done by multiple tools.

RAISED KNOT

Manual workout around the knots randomly, highlights the knots in appealing and aesthetic angles.

SAWNMARK

A classic way of expressing the wood cut, includes regular and irregular sawnmark.

Color

NATURAL

The general term of traditional colors, e.g.: Natural Oiled / Lacquered, White Oiled / Lacquered; It is made by the transparant natural oil with different pigments (Regular Stain) for the accordant color request.

SMOKED

A classic and welcome way to creat the color, Ammonia reacts with tannin in wood resulting in darkening and spontaneous color tone; There are kiln smoking and spray smoking to do different degrees.

CARBONIZED

A heat-pressured tank makes the color happen, the process ensures the flooring products in a decent dark tone with less color variation. More stable to afterwards enviromental changes.

REACTIVE STAIN

By use of various compounds reacting with tannin in wood, it brings out the stylish layering of colors; In order to achieve the high-point of coloring, there is manual wash involved; MEFLOOR has managed the reactive colors stability.

TOPPING

A complicated upgrade of Regular Stain, it enables the surface with more delicate and lively color effect with at least 2 time staining and polishing.

IMMERSED

Designed to improve the Reactive Stain, to soak the veneers into the pool by controls of water temperature and immersing time; the output is more harmonious in color variation.

BURNT

True to its name, the boards surface are thermo treated by flamethrower to get the dramatic and volcanic style, such flooring is widely used in the antique and architecture concept.

Grading

SELECT

NATURAL

CHARACTER

ROBUST

Pattern

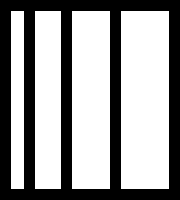

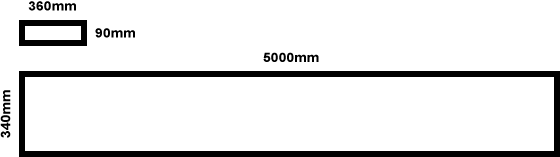

PLANK

- 1200 x 150 x 10mm

- 1900 x 190 x 12mm

- 1900 x 190 x 14mm

- 1900 x 190 x 20mm

- 2200 x 220 x 14mm

- 2200 x 220 x 15mm

- 2200 x 220 x 20mm

- 2200 x 260 x 14mm

- 2200 x 260 x 15mm

- 2200 x 260 x 20mm

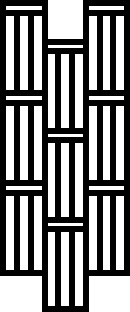

CHEVRON

- 750 x 150 x 14mm

- 750 x 150 x 15mm

- 740 x 190 x 14mm

- 740 x 190 x 15mm

- 1040 x 190 x 15mm

VERSAILLES

- 800 x 800 x 20mm

FRENCH FLOOR

Different widths installed next to each other, normally configured 150mm / 190mm / 220mm / 260mm

DUTCH FLOOR

- 1890 x 270 x 15mm

CUSTOMIZED

Tailor-made sizes available

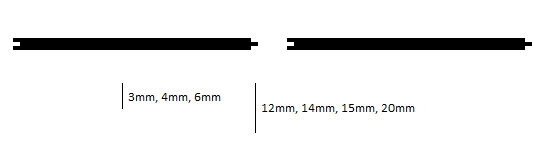

Profile

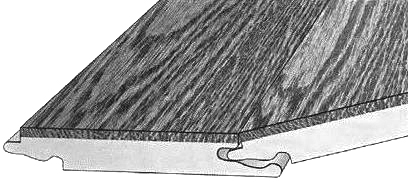

TONGUE & GROOVE

CLICK

Criteria